| B&B

Pipe and Tool Services |

| |

SLOTTING

|

| |

| B&B

Pipe and Tool Co. offers a wide range of

choices, enabling our customers to determine the

most effective slot arrangement for them. Using

state-of the art 16 spindle slotting machines,

our highly skilled technicians cut precision

slots radial to the center of the pipe. At a high

production rate, slotted pipe is milled under

close tolerances, resulting in clean openings and

consistent slot width throughout the entire pipe.

Therefore, no excess metal is removed which

preserves maximum pipe strength. Slots can be

furnished 1

1/2" to 3" long for pipe of any length

with either standard threads and couplings or

flush joint threads Before slotted pipe is

delivered to our customers, all threads and

couplings are thoroughly cleaned and lubricated,

and the pipe interior is free of burrs or loose

metal chips.

|

| |

|

| SLOTTING

OPTIONS: |

| |

|

| Type

of Slots Available: |

|

| |

|

Keystone

Slots: Keystone

Slots:

- Slots are

milled wider on pipe interior and are

self cleaning to help prevent clogging. A

6° included-angle slot is standard.

Slots are available in widths .030"

to .125" in pipe sizes, 4.500"

to 10.750" OD.

|

|

Straight

Slots: Straight

Slots:

- Slots

furnished inline or staggered in pipe

sizes from 1.900" to 20" OD

with gauge openings from .012" to

.500". Slots are of equal width

throughout the pipe.

|

|

| |

|

| Slot

Patterns Available: |

|

| |

|

Straight Vertical Slotted

Pipe Straight Vertical Slotted

Pipe

- Slots cut

radial to center which causes the

incoming fluid to flow directly to the

center eliminating the possibility of any

swirling action inside the pipe. Slots

furnished in sizes from 1.900" to

20" OD with gauge openings from

.012" to .500".

|

|

| |

Staggered

Vertical Slotted Pipe Staggered

Vertical Slotted Pipe

|

|

| |

Multiple

Vertical Staggered Slotted Pipe Multiple

Vertical Staggered Slotted Pipe

- Slots

increase the inlet openings from one to

four additional parallel vertical slots.

This type of slotted pipe is available in

sizes ranging from 2 3/8" through

20" OD.

|

|

| |

| THREADING

TO API SPECIFICATIONS |

| |

| API

Threads with couplings are extra strong for deep

and high-deviated wells. Where tensile and axial

loads on casing are high, such as that

encountered in deep high-angle holes, extra joint

strength is needed. Our Landis threading machines

produce this extra strength with API Threads

either short, long or buttress. |

| |

Buttress

threads offer

extra strength since the horizontal effect of

tensile load is less than friction load, thus

minimizing the risk of jump-out and the resulting

joint failure. Buttress

threads offer

extra strength since the horizontal effect of

tensile load is less than friction load, thus

minimizing the risk of jump-out and the resulting

joint failure. |

|

Couplings

are

long enough to fully engage runout threads, thus

providing joint strength virtually equal to

original pipe strength. Couplings

are

long enough to fully engage runout threads, thus

providing joint strength virtually equal to

original pipe strength. |

|

| |

| B&B

furnishes API tubing and casing couplings. |

| |

| SECURITY

FLUSH JOINT THREADS/ |

| VENTURA

FLUSH JOINT THREADS |

| |

| Ventura/Security

flush joint threads are still an effective

connection for oilfield liners! Flush joints, a

standard of the drilling industry, continue to

serve the purpose for which they were designed: A

strong connection between pipe sections, flush

inside and out, without couplings! The thread

profile is a modified buttress type. The reverse bevel of the

outer (Primary) shoulder tends to prevent the box

from spreading during joint make-up while

providing an outer fluid pressure seal.

|

| |

|

|

| |

|

The

Ventura/Security Thread utilized in flush joints

can withstand all the destructive forces imposed

on well liners downhole. In addition they provide

additional advantages: The

Ventura/Security Thread utilized in flush joints

can withstand all the destructive forces imposed

on well liners downhole. In addition they provide

additional advantages:

- High

resistance to damage in stabbing

- Minimimum

revolutions required to make-up and

shoulder the joint

Available

Sizes: Up to 8 5/8" OD Casing

|

| |

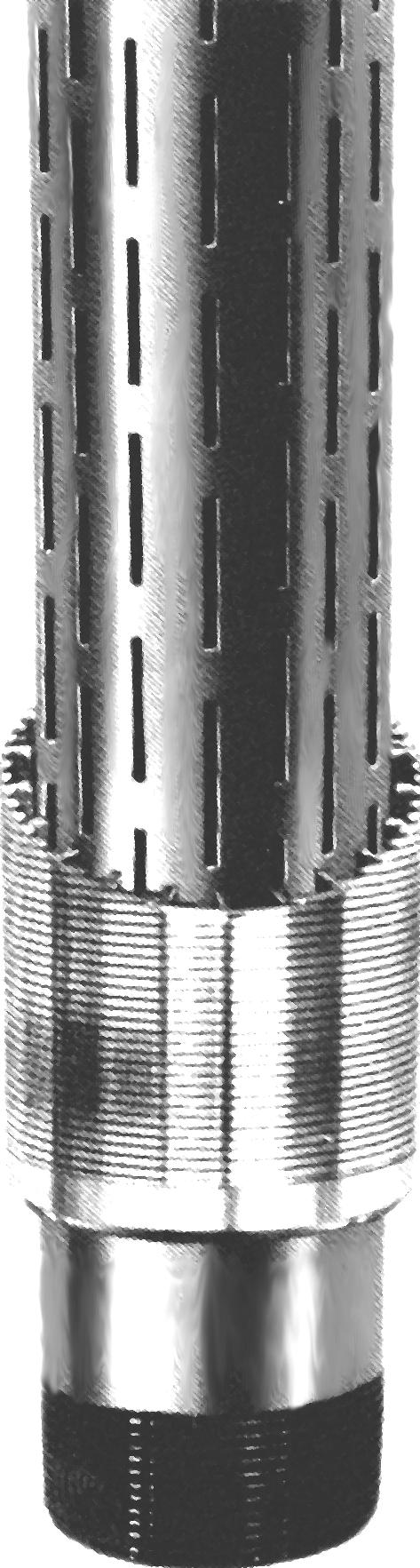

| WIRE WRAP

SCREEN INSTALLATION |

| |

| Traditionally

gravel packed slotted liners have provided

strong, rugged screens that allow oil and

formation fluids to enter the well bores. In some

reservoirs, however, it has been necessary to use

finer gravels. As a result wire wrap screens have

been developed to provide .008" to

.020" openings to control this incursion

problem. To maintain maximum strength in the well

bore, these screens are normally installed on

slotted base pipe. |

|

| |

| GRIT

BLASTING |

| |

| B&B Pipe

and Tool Co. offers the only grit

blasting facility capable of grit blasting tubing

and casing from 2 3/8" OD through 13 3/8 OD

in California's San Joaquin Valley. |

| |

|